The buzz around Industry 4.0 is reaching new heights, and it has become a trending topic in Indonesia. This is because Industry 4.0 revolutionizes the way we work by potentially replacing human jobs with robots. To cope with this, the national manufacturing sector must be prepared for significant changes in embracing the fourth industrial revolution or Industry 4.0. Consequently, new approaches and capabilities are required to build innovative and sustainable production systems.

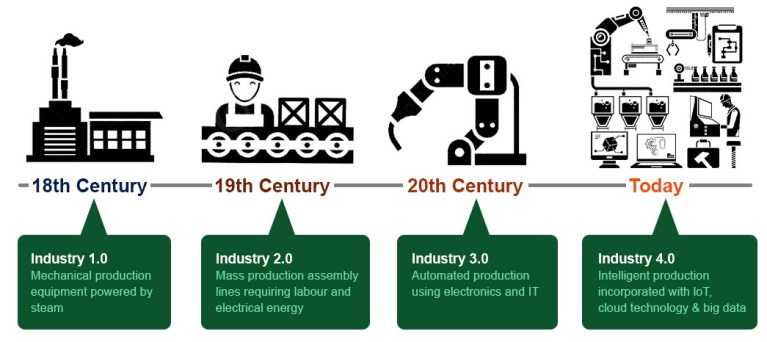

But what exactly is Industry 4.0?

The term “Industrie 4.0” originated from a project within the German government’s advanced technology strategy, focusing on the computerization of factories. The term was reintroduced at the Hannover Fair in 2011. In October 2012, the Working Group on Industry 4.0 presented recommendations for implementing Industry 4.0 to the German federal government.

According to Wikipedia, the fourth industrial revolution has four principles that enable every company to identify and implement various Industry 4.0 scenarios, including:

The Industry 4.0 revolution will bring about many changes, with all its consequences. Industries will become more compact and efficient. However, there are also risks that may arise, such as a reduction in human resources due to replacement by machines or robots.

The development of the Industry 4.0 revolution undoubtedly has positive and negative impacts on various aspects of life. One of the advantages of implementing the Industry 4.0 model may outweigh the concerns that arise. This applies to many production facilities. In highly hazardous work environments, human health and safety can be dramatically improved. Supply chains can be better controlled when data is available at every stage of manufacturing and delivery processes. Computers acting as “controllers” can produce more reliable and consistent production. Additionally, the results for many businesses can increase revenue, market share, and profits.

Professor at the Department of Architecture, Faculty of Engineering, Universitas Indonesia, Yandi Andri Yatmo, expressed this during a discussion with Kompas.com in Jakarta, on Saturday (30/3/2019). “Ultimately, technology is used to preserve existing resources, not deplete them. This means resources from nature,” said Yandi. According to him, the current era of the fourth industrial revolution makes building design more responsive to users and natural changes.

Despite advancements in innovation and technology, the Industry 4.0 revolution also has negative impacts that are feared to occur in Indonesia. Some negative impacts that are feared and have occurred in several countries include:

To address the concerns that may arise in Indonesia, the Ministry of Industry has prepared several strategies to improve Indonesia’s competitiveness in the Industry 4.0 era. The Expert Staff of the Minister for Increasing the Use of Domestic Products at the Ministry of Industry, Imam Haryono, said one of the strategies prepared is through the Making Indonesia 4.0 program. “Making Indonesia is one of the national development agendas to accelerate the achievement of aspirations to become one of the world’s top 10 economies by 2030,” said Imam in Jakarta, on Thursday (31/1/2019). Furthermore, according to Imam, they will strengthen vocational training towards a dual system, develop Poltek/Akom in industrial areas, link and match, 3 in 1, industrial workforce competency certificates, and human resource development.

In conclusion, the fourth industrial revolution is a revolution introduced by Germany. To avoid the negative impacts of this revolution, it is necessary for every individual to explore creativity and develop innovations to become individuals ready to face the revolution happening in the world.

So, Are you ready for Industry 4.0?